At FAHRNER Industries, plastic machining enables the production of custom technical parts from sheets, rods, or tubes. Thanks to our team’s expertise, we combine mastery of technical know-how, high-performance materials, and ISO 9001 quality certification to deliver parts that meet the strictest requirements in terms of quality, tolerances, reliability, and performance.

Plastic Machining: Manufacturing Techniques and Materials

Plastic machining is a manufacturing process where material is removed from a sheet or block to obtain a custom part. Whether by CNC turning and/or conventional turning, 3 to 5-axis CNC and/or conventional milling, or even laser cutting, plastic machining offers high precision, with standard tolerances according to ISO 2768-mK, less than ±0.05 mm, and in technical materials with specific properties.

At FAHRNER Industries, we manufacture parts to drawing, from single units to large series.

Turning

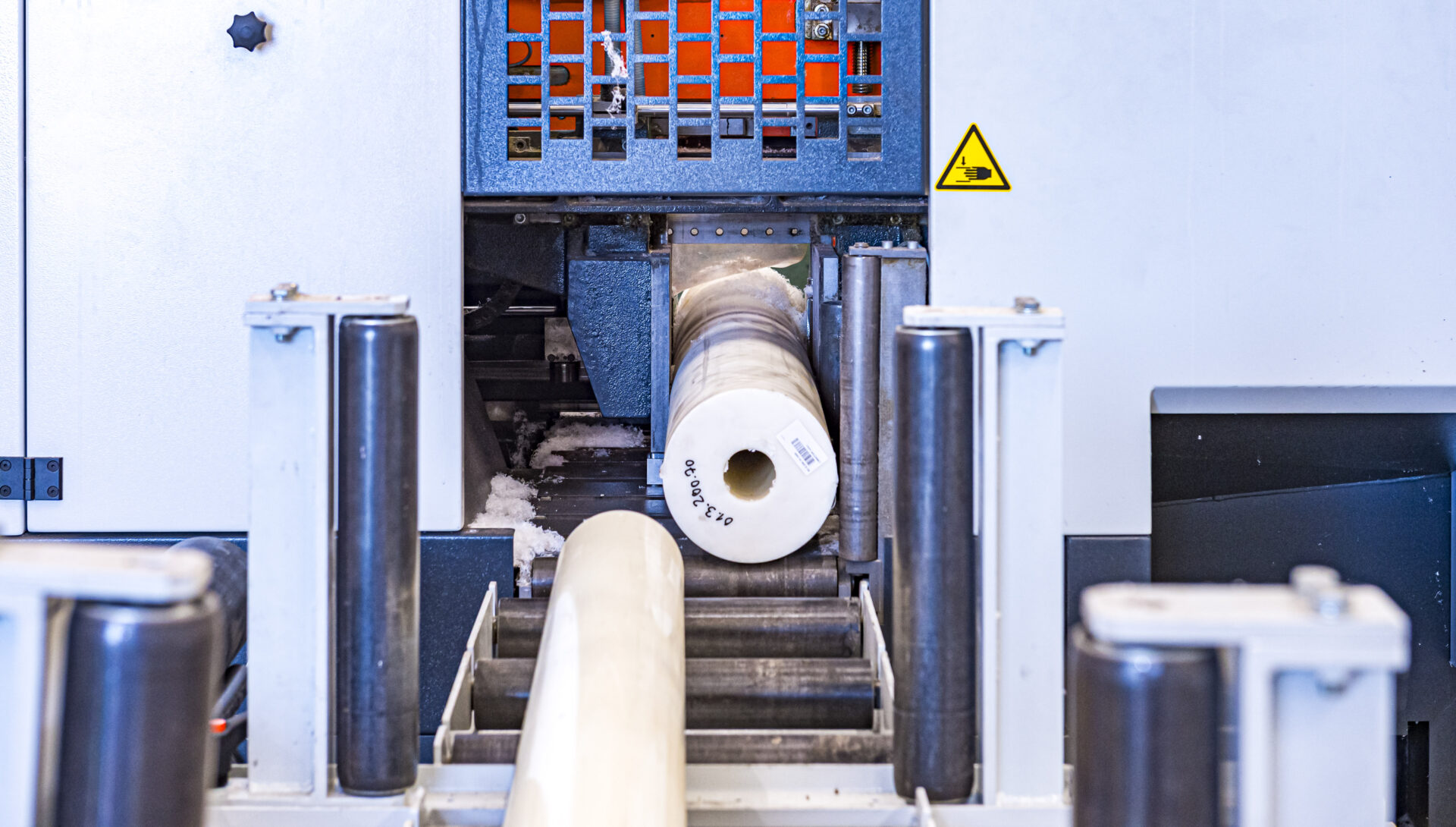

Turning enables the production of rotational parts such as rings, pulleys, spacers, rollers, gears, etc. Fixed in a chuck or bar feeder, material is removed using cutting tools.

Machining a rotational part is done on different machines, depending on its complexity:

- Conventional lathe: Ideal for single parts or small series with simple geometry.

- Small CNC lathe: Ideal for single parts, prototypes, and small series. This is the preferred machine for training and apprenticeships.

- Dual-spindle CNC lathe: Suitable for medium and large series.

- CNC lathe with milling axes: For machining that combines turning and milling. This allows for the production of complex parts with high precision, such as threaded sliders, pulleys with grease fittings, etc.

We apply standardized ISO 2768-mK tolerances while adapting to specific customer drawing requirements.

3 to 5-Axis Milling

Milling allows machining of blocks or sheets by material removal, combining two movements: the rotation of the cutting tool and the advance of the head. The part or sheet is held by vacuum suction or mechanical clamping with pneumatic vises.

Milling is suitable for all types of technical parts, on 3 or 5 axes:

- 3-axis milling: Suitable for simple parts requiring mainly contouring, drilling, chamfering, etc. Serial production is favored.

- 5-axis milling (positioned or continuous): Ideal for complex multi-surface parts, with simultaneous rotation of the B and C axes, enabling parts to be produced according to their 3D model.

Unlike turning, there is no limit to the types of parts with milling, allowing for diverse shapes and dimensions. Programming and machining strategy are crucial for optimizing cycle times and minimizing rework. 3 and 5-axis milling reduces rework while increasing precision on complex geometries.

From Reception to Shipping

At FAHRNER Industries, every plastic machining project is managed to guarantee part quality, customer satisfaction, and on-time delivery. Upon receipt of the manufacturing order and customer drawing, a complete analysis is conducted to identify technical requirements, production mode (single or serial), and machining process (turning or milling).

Once the material is prepared, the machining program is created by our technicians, who then set up the equipment. Quality checks are carried out at various stages of the manufacturing process, depending on the part and series. For single parts, a full inspection is performed on all dimensions. For serial parts, the first part is fully inspected, then sampling control is implemented in accordance with the AQL standard.

Each production is supervised by a process pilot, the true conductor of production. They ensure overall coherence: program conformity, material availability, planning, part quality, and monitoring of any non-conformities. Thanks to this rigorous and transversal organization, FAHRNER Industries guarantees reliable deliveries, compliant parts, and high-quality customer support.

Our Materials

| Material | Operating Temperature | Main Characteristics | Technical Advantages | Typical Industrial Applications |

|---|---|---|---|---|

| PA (Polyamide) | -40 °C to +100 °C | High mechanical strength, good wear resistance, good sliding properties, moisture absorption, good chemical resistance | Excellent abrasion resistance, good vibration damping, high machinability | Gears, bearings, guide parts, wear parts for industrial machines, pulleys, rollers, etc. |

| HDPE (High Density Polyethylene) | -50 °C to +60 °C | Good chemical resistance, low density, good impact resistance, good machinability | Good corrosion resistance, insensitive to moisture, easy to weld and machine | Tanks, containers, sliding pads, parts for the chemical and food industries |

| POM (Polyacetal) | -40 °C to +100 °C | High dimensional stability, good mechanical strength and rigidity, low coefficient of friction, low moisture absorption | Dimensional precision, excellent sliding properties, fatigue resistance, good machinability | Gears, precision parts, pump components, parts for automotive and electrotechnics |

| PET (Polyethylene Terephthalate) | -20 °C to +115 °C (up to 180 °C peak) | High mechanical strength, excellent dimensional stability, very low moisture absorption, good wear resistance | Creep resistance, thermal stability, good sliding properties, good chemical resistance | Bearings, rollers, wear parts, components for textile and packaging machines |

| PP (Polypropylene) | 0 °C to +100 °C | Low density, good chemical resistance, good fatigue resistance, good electrical insulation | Corrosion resistance, easy to weld, good flexural strength | Parts for the chemical industry, food applications |

| PEEK (Polyetheretherketone) | -60 °C to +250 °C (up to 310 °C peak) | Very high mechanical and thermal resistance, excellent chemical resistance, exceptional dimensional stability, autoclavable | Resistance to temperatures > 250 °C, wear and creep resistance, excellent sliding properties, food and medical contact compatible | Components for aerospace, parts for the medical industry, high-performance bearings and bushings, extreme condition applications |

Beyond their light weight, plastic materials offer many advantages for the industrial sector. Optimizing sliding and rolling, resistant to chemical, mechanical, and extreme weather conditions, technical plastic parts are durable and high-performing over time. At FAHRNER Industries, we have more than 250 tons of material in stock.

Need advice? We assist our clients in choosing materials according to the mechanical, thermal, chemical, or electrical constraints required by your specifications.

Applications of Technical Plastic Parts

Plastic machining offers numerous advantages for industrial sectors such as:

- Lifting and handling: To optimize the sliding of telescopic masts, the rolling of mobile trolleys on various cranes, technical plastics are the solution for the longevity of your equipment.

- Conveying: Modular and interchangeable, to ensure stability and reliability.

- Food industry: For conveyor equipment, with guides, slides, distribution stars, and other components in contact with food.

- Maritime and naval: To ensure high resistance and lightness with unbreakable parts.

- Railway and mining: For electrical insulation, protective coverings, and robust, durable components.

- Medical: Assembly of sub-assemblies with high resistance to sterilization cycles.

- Safety glazing: To ensure the safety of people in the most critical situations.

Why Choose FAHRNER Industries?

FAHRNER Industries offers complete control over the production chain, from procurement and material stocks to quality control, making us your trusted partner for delivering ready-to-assemble parts. ISO 9001 certified, we guarantee custom-made parts tailored to your specific needs. We are committed to rigorous management through quality and process indicators, hands-on team involvement, and a quality system aligned with our growth strategy.

Our Values

- Respect for strict tolerances

- Responsive and personalized customer support

- Teams dedicated to customer satisfaction, part quality, and meeting deadlines

- Flexible and custom production, from single units to small and medium series

- Complete mastery, from order to shipping

- Continuous improvement and internal skills development

Do you have a plastic machining project? Contact our experts for personalized support!