Established in 1987, PLASTRANCE manufactures custom-made machined and thermoformed parts in small and medium production runs. Each project is precisely tailored to our customers’ specifications and drawings using state-of-the-art equipment.

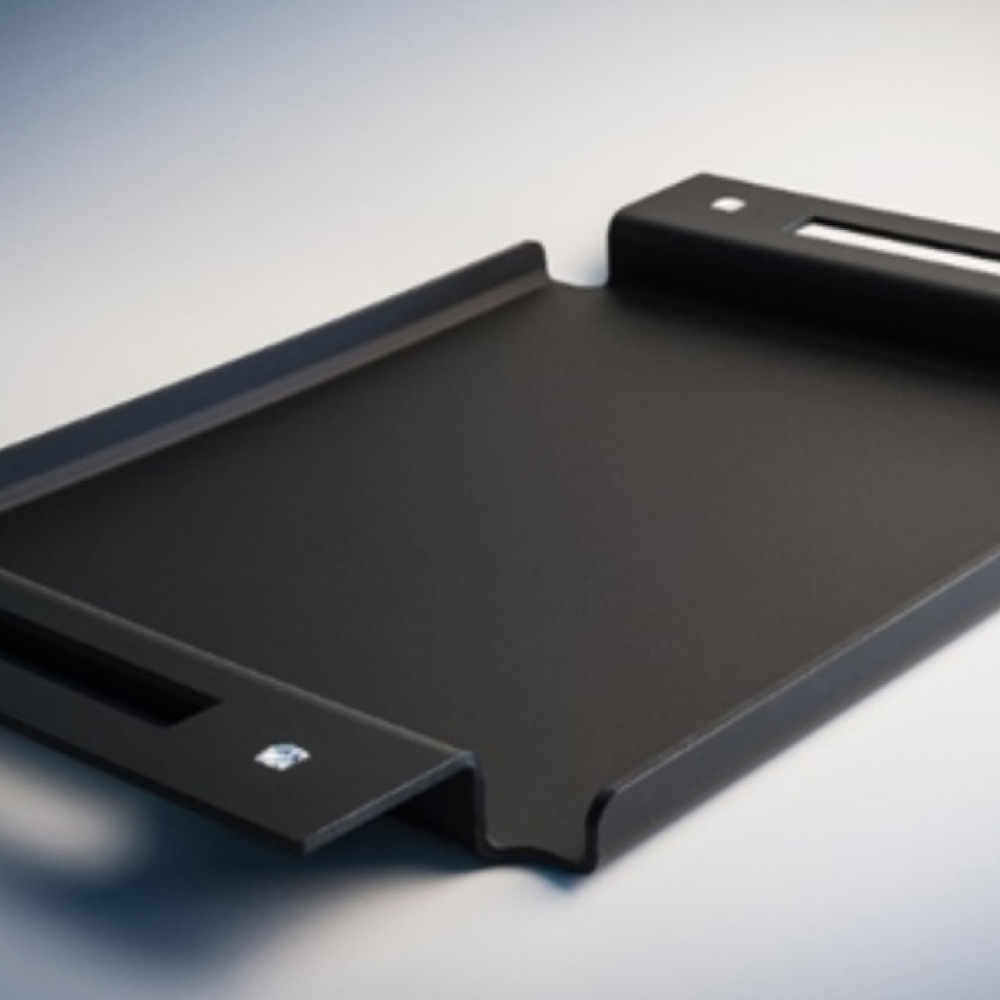

Specialising in plastics processing, PLASTRANCE manufactures a range of optical quality polycarbonate safety glazing.

The plant is distinguished by its expertise in thermoforming and draping, two processes for shaping thermoplastic materials from 1 to 15 mm thick. Today, 80% of the plastics processed are transparent. Our thermoforming processes guarantee high quality results, tailored to specific requirements and a wide range of applications. We guarantee impeccable optical quality for our PMMA and polycarbonate substrates.

PLASTRANCE also offers a high-performance coating service for all types of thermoplastic surfaces, guaranteeing enhanced protection against scratches, UV and chemical aggression, while optimizing the aesthetics and durability of the materials.

PLASTRANCE has been ISO 9001:2008 certified since 1993, demonstrating our commitment to quality. This certification attests to our ability to optimize our performance, continuously improve our products and services, and offer rigorous control at every stage of the process.

Key figures

95%

of our glazing is for the automotive industry

80%

of polycarbonates have an anti-abrasion coating

70%

exported internationally

CONTACT

-

4-6 rue de Berlin

Parc des collines

F68350 Brunstatt-Didenheim